SPI

To ensure a proper electrical connection on the PCB board, solder paste must be applied correctly. Before the PCB assembly process starts, the solder paste is inspected to see whether it has been placed appropriately.

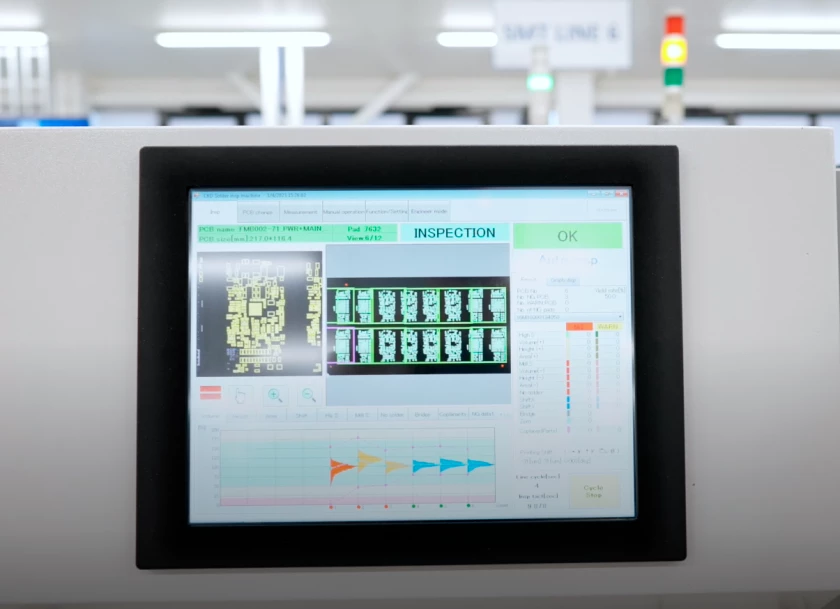

Pasted PCB boards go straight to the solder paste inspection machine. It has a monitor which displays the inspection process and results. The machine shows printing trends and features and configurable statistic presentation. To determine if the proper quantity of solder paste is applied, and to ensure that there are no inconsistencies on the PCB contact pads, 2D and 3D images are taken. It is done by two projectors which use striped pattern light to project pictures of solder. The equipment also gives adjustments to the screen-printing machine based on data from inspection results. Additionally, it scans the PCB's barcode, allowing the inspection results to be recorded.