Pick and place

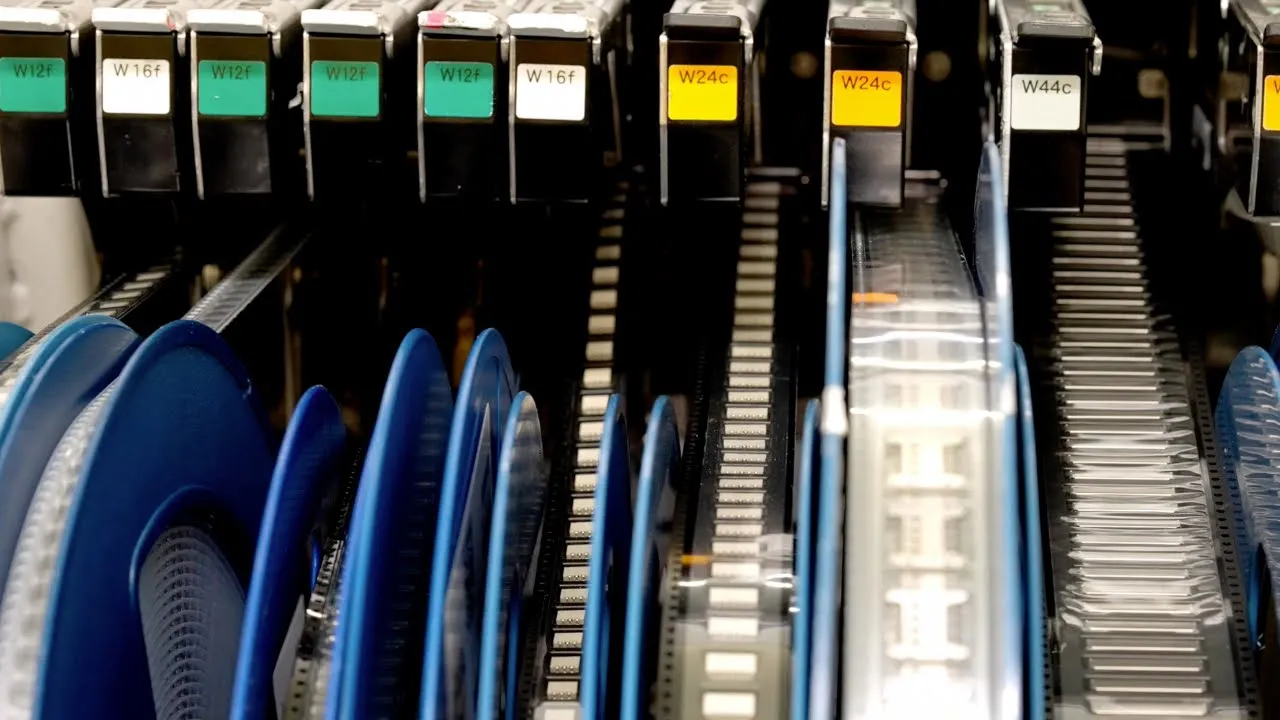

We use highly productive pick and place machines for the component placement process, which begins as soon as the accuracy of the solder paste application is verified. Based on PCB board layout and bill of materials, the SMT programmer sets up the machine. Project-specific surface mount devices (SMD) are then loaded by the SMT operator to the feeders at the prescribed locations. SMD components arrive in reels or trays and are loaded to feeder magazines based on their size. Each component reel has a data matrix that is scanned and inserted into the SMT system. An automated system ensures accuracy by rejecting any incorrect reels. By scanning the next one, reels can be simply replenished.

The pick-and-place machine receives the PCB board and places the components on the pasted panels. To pick up pieces and subsequently deposit them into the solder paste on the board, special nozzles employ vacuum.

Small chips, large ICS, and other complex components can all be assembled by this precision machinery.