ODM ELECTRONICS DESIGN SERVICES

DEVELOPING AND IMPROVING THE CONCEPT

Our experienced product design team can act as your company's engineering department. Or we can combine our strengths with the product development team of your company. At the end of the concept phase, we prepare a proposal for product development, outlining the possible product performance, the approximate development schedule and cost estimates.

PRODUCT CORRECTIONS

Redrawing PCBs according to customer requirements;

Converting PCB layout into Altium format file type;

Redesign of PCBs by replacing components that have expired or reached the end of their service life (EOL);

Product engineering update: we install or upgrade additional functionality to the product.

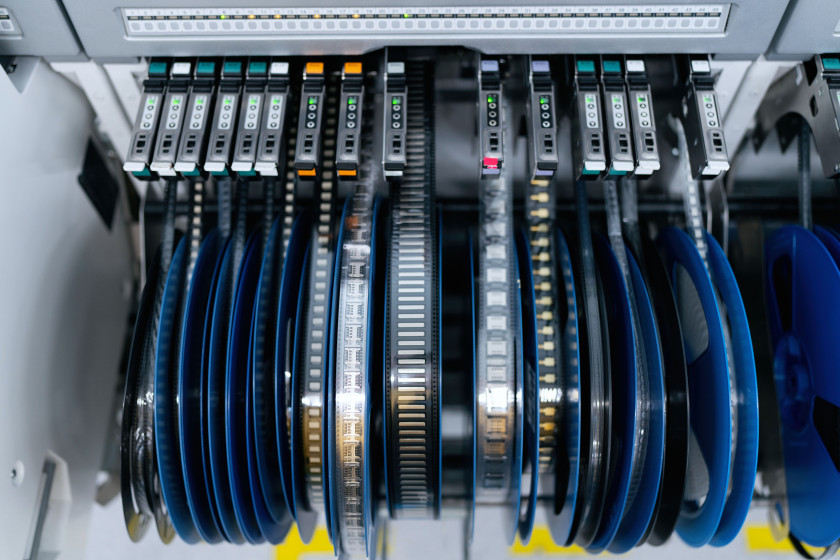

BILL OF MATERIALS (BOM) OPTIMIZATION

Our component database allows us to estimate the life cycle of components, so that we can analyze the components provided in the projects and update them if necessary.

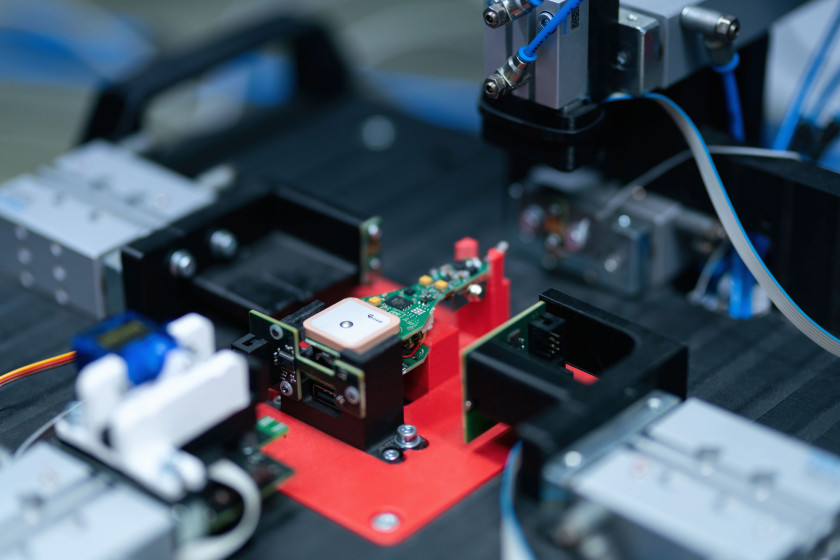

DEVELOPMENT OF TEST BOARDS

Our engineering team is responsible for the quality of the devices. As a result, we design a personalized test fixtures to meet the needs of our customers and ensure that they receive properly functioning devices. Planned operational scenarios and documentation follow the testing process. We check the operation of various connectors, software systems and signals, such as WI-Fi, Bluetooth, LoRa, ZigBee and others. According to our customer's production capacity, we offer both robotic and manual product testing.