Litavimo kokybės patikra

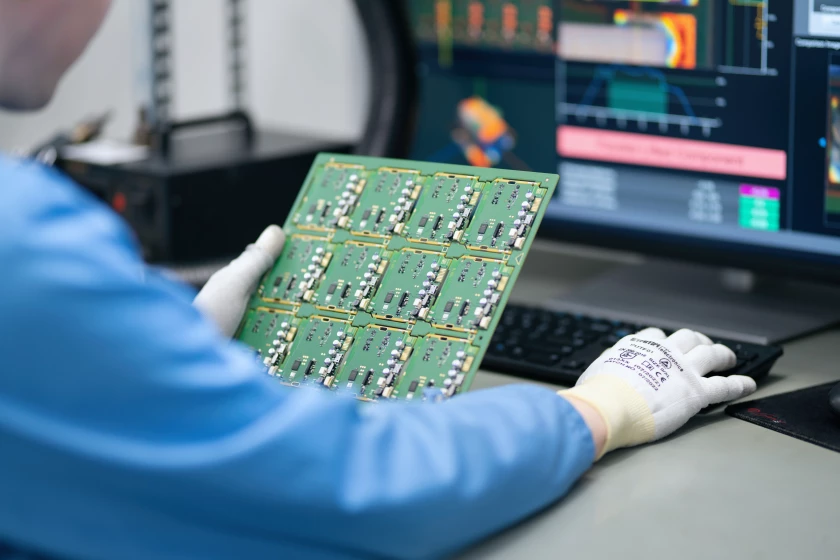

Kai komponentai išdėlioti ant PCB, o plokštė sėkmingai įkaitinta ir sulituota – būtina patikrinti ar surinkimas atitinka inžinierių užduotus parametrus. Tam gamyboje naudojame kompiuterinio matymo sistemas AOI (Automated Optical Inspection).

Pagrindinis šių įrengimų uždavinys – fiksuoti surinkimo ir sulitavimo kokybės neatitikimus, bei juos iliustruoti trimatėmis gaminio projekcijomis. AOI įrenginys pasinaudodamas filmavimo kameromis skenuoja PCB ir identifikuoja defektus tokius kaip: pamesti komponentai, poliariškumo klaidos, neprilituotos kojelės ir kiti.

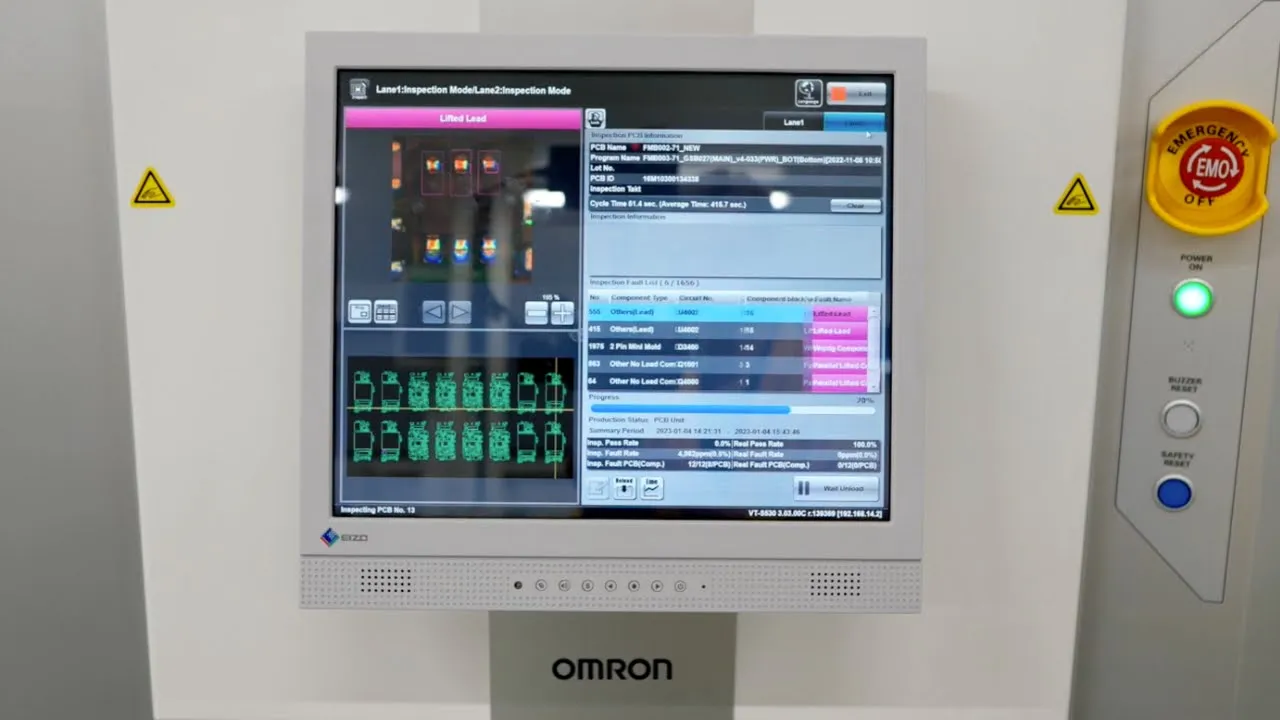

Naudojame įrengimus, kurie palaiko dviejų konvejerio linijų aptarnavimą. Įrenginiuose sumontuotos kameros fiksuoja ir kuria gaminio trimatį modelį, o speciali programa pažymi neatitikimus bei pririša juos prie gaminio duomenų matricos. SMT linijos pabaigoje remiantis šios patikros rezultatais plokštės išrūšiuojamos į patikrą praėjusias bei papildomo patikrinimo reikalajančias plokščių lentynas.

PCBA Plokštės, kurios nepraėjo automatinės optinės patikros (AOI) tikrinamos papildomai. AOI operatorius nuskaito PCB plokštės duomenų matricą ir peržiūri sistemos padarytas nuotraukas. Programa automatiškai atpažįsta neatitikimus, ekrane parodomas numatomas komponentų išdėstymo rezultatas. Įvertinęs pateiktą informaciją AOI specialistas nusprendžia, ar problemą galima išspręsti vietoje, ar plokštę reikia perduoti perdarymui. Smulkius litavimo neatitikimus AOI specialistai apmokyti koreguoti vietoje.

Jei automatinė plokščių patikra be pagrindo identifikuoja problemas, AOI specialistai atitinkamai koreguoja automatinės optinės kontrolės programą.