THT

Through-hole technology (THT) is used for bigger and more complicated component assembly.

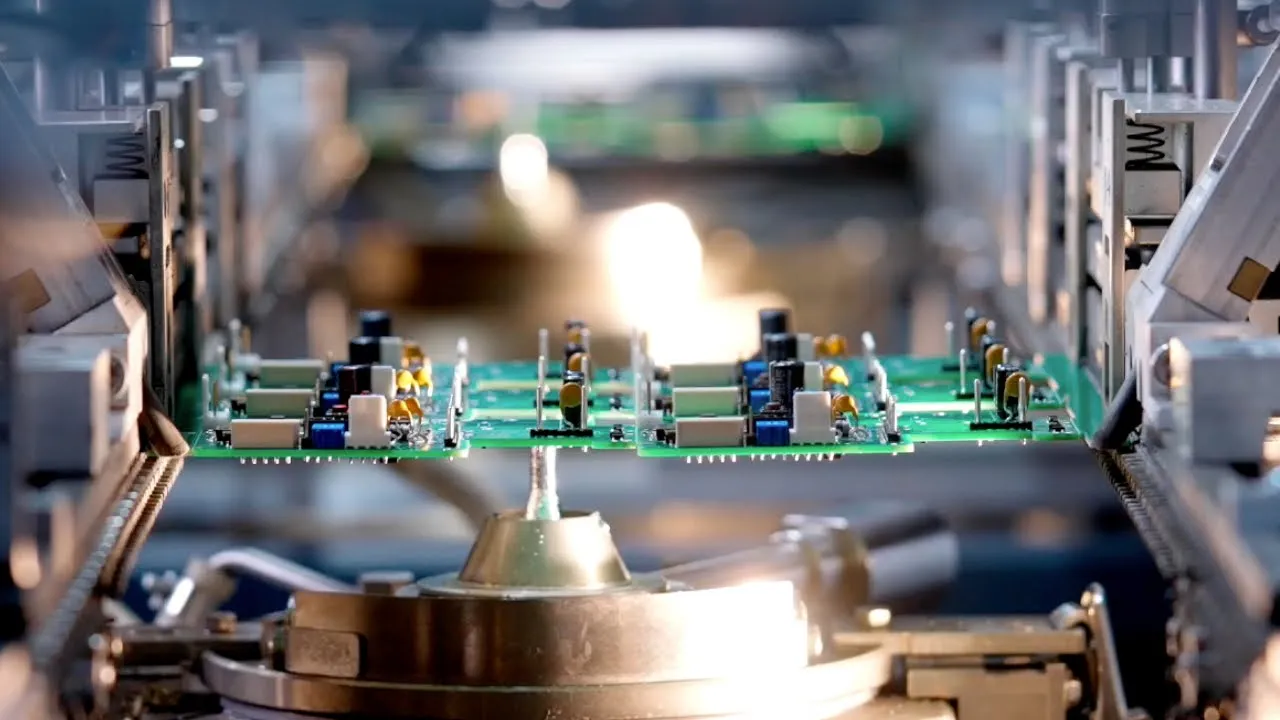

For efficient mounting of THT components, we use an automatic selective soldering machine ERSA Versaflow. The operator places the THT components on the board via a designated scheme and enters the PCB into a board loader.

The process begins with the preheating of the PCB to a specific temperature in order to prepare it for soldering. This helps to remove any moisture or contaminants from the surface of the PCB board and makes the solder more flowable. Next, a flux solution is applied to the PCB to help the solder flow and adhere to the surface. The solder is then applied to the PCB using a nozzle or soldering iron that is precisely controlled to apply the solder only to the desired soldering points.

Once the solder has been applied, the PCB board is cooled to solidify it. Finally, the PCB is cleaned to remove any excess flux or solder. This process is typically automated and can be used to join a wide range of components, including through-hole and surface mount components, to the PCB.