PLASTIC INJECTION MOULDING: HALF-YEAR'S STATISTICS AND OUTLOOK

#plastics, #ems, #manufacturing, #plasticinjectionmoulding

In our pursuit of becoming a one-stop shop electronics manufacturing partner, this year, we have started the production of plastic parts and casings. We produce plastic parts required for electronics box-build – enclosures and other plastic elements. This resulted in over 3.8 million plastic components for GPS, networking devices, and various other industries produced to this date.

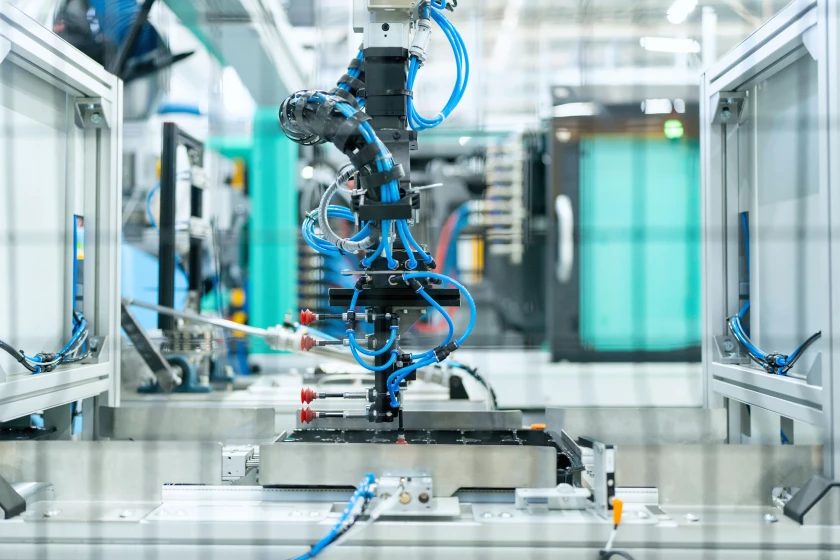

Robotized equipment

Emphasizing efficiency, we focus on automation and production agility while introducing new services and equipment on our production floor.

The robots we use for plastic injection moulding process come in two different varieties. In the first, solidified plastic components that are ejected from the mould cavity are picked up by robotic hands. Other robots quickly gather finished plastic forms into the trays. As a result of this process not requiring manual labour, plastic manufacturing time is decreased by about 25–30%.

Our robotic grippers can adapt to a variety of precision plastic shapes, so there is no need to design special, individual grippers for each device, which shortens the project cycle.

Waste recovery

Our production process has a low scrap rate, just 1.65% during the last four months. We established a material recovery system in March to extract recyclable parts. So far, through re-milling more than 16,000 components, 180 kg of material have been recovered. This results in lower waste and expense recovery.

Moving forward to one-stop shop concept

In addition to making plastic parts, we are getting ready to shift mould manufacture in-house with the aim of starting to make plastic injection tooling by mid-Q1 2024. By producing prototype plastic moulds in-house, we can reduce the time required for production, enabling faster iterations and a shorter time to market. As part of our strategy to establish ourselves as a one-stop shop provider, we keep improving the effectiveness of our supply chain and broadening the range of services we offer.