NEW CONFORMAL COATING EQUIPMENT AT TELTONIKA TECHNOLOGY CENTRE

#manufacturing, #ems

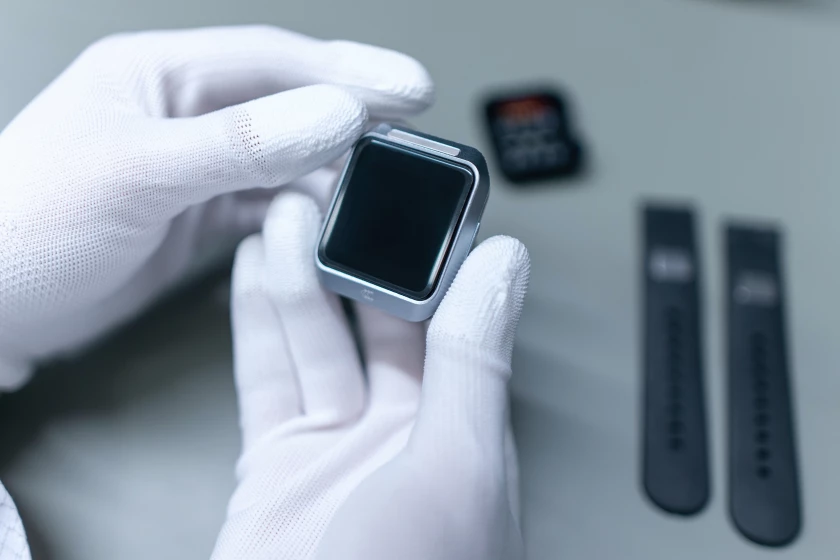

The Teltonika Technology Centre, electronics manufacturing facility which opened last autumn, recently received new equipment, which streamlines the production flow. The facility's space enables us to execute projects in-line and orderly, from receiving components to box-build.

Conformal coating

In July, we installed new conformal equipment. Coating PCBs (Printed Circuit Boards) provides protection against factors such as moisture, dust, chemicals, temperature variations, and mechanical stress. Thus enhancing PCBs' reliability and lifespan. Conformal coating is used in diverse industries requiring specific protective measures.

This process is typically essential for medical electronic devices. It helps protect electronics from bodily fluids, sterilization processes, and possible contaminants in medical environments. We hold ISO 13485:2016 medical standard and currently produce telemedicine, wearables, so coating equipment is especially needed.

New equipment

We use the ASYMTEK Select Coat SL-940 Conformal Coating System and UVLED 395 curing system. Loading, coating, curing, and unloading are all completely automated and inline processes. The technology utilizes a non-volatile UV coating that sets up quickly in UV light. Precise coating coordinates identify spots that need coating or should be left uncoated. Numerous coating nozzles ensure accurate filling and application.

Having conformal coating equipment in-house helps us achieve flexibility and faster turnaround time. This improves product reliability and allows us to respond quickly to partner needs or changes.

Teltonika EMS facilities currently offer plastic injection moulding, electronics assembly, testing, and box-build services. Our partners successfully implement and expand their projects. It is achieved by global partner network, R&D, manufacturing know-how, and extra capacity dedicated to partners.