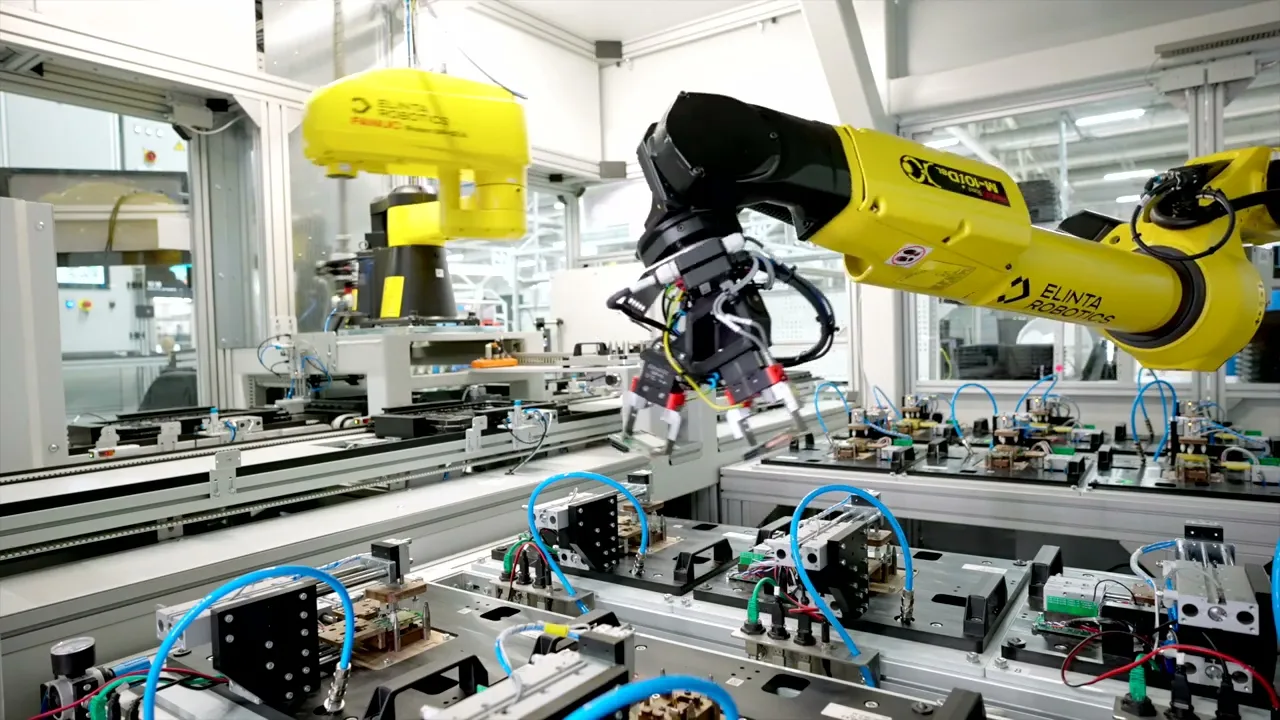

Robot assisted testing

Testing is one of the most crucial and time-consuming electronics manufacturing steps. To make this process more efficient and fast, we use testing robots. Systems are equipped with two robotic hands and can serve 16-24 testing fixtures. The robotic cell is separated into two sides, and each of them can test one specific product. The firmware is flashed before testing.

The operation sequence is as follows: an operator loads the robot with a stack of trays with untested devices. These trays are specially designed for robotic operations. As soon as the tray enters the robot, scanners verify that the right tray has been fed for testing. The SCARA robot then retrieves the device from the tray and puts it on a stable base, enabling a stable and accurate PCBA position to minimize the impact of handling errors. The PCB board is taken from the base by the assistant robotic hand and brought to the testing fixture. It completes the testing cycle and logs all necessary testing data into our production management system. When testing is complete, the robot places the device back into the steady base, where SCARA picks it up again and places it either in the pass or fail section according to the testing data. The combination of both robots creates synergy, enabling the electronics testing process to be faster and more precise.