ELECTRONICS MANUFACTURING PARTNER

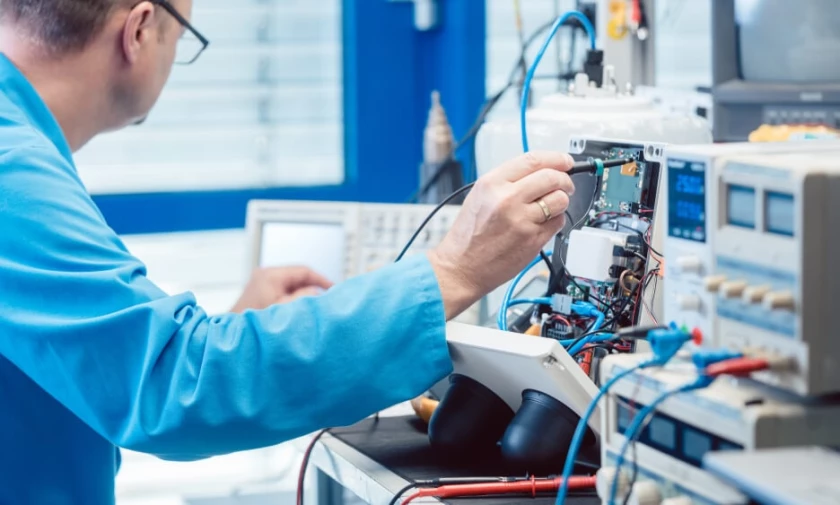

ODM ELECTRONICS DESIGN SERVICES

The competitive advantage of Teltonika is the side by side work of our production and engineering staff. We have a full development department with several engineers for the development of electrical circuits, circuit board designs and mechanical designs. Our parts sourcing experts help to organize the most stable supply chain. This team can help to design or redesign your business idea.

EMS Electronics assembly

We help companies increase their profitability by optimizing the cost of electronics manufacturing and assembly. Our global partner network helps reduce the risks and associated costs of the supply chain of electronics components. Our goal is to deliver products to our customers on time and without disruption.

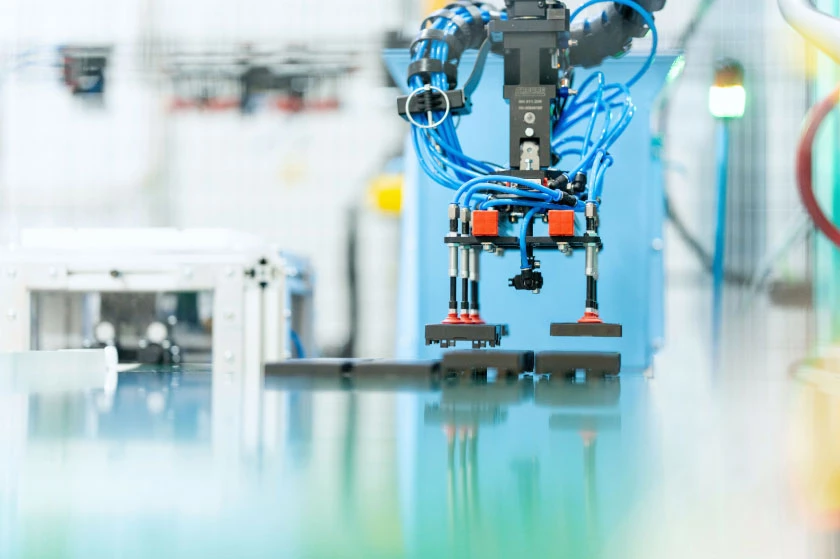

plastic injection moulding

Applying a local-for-local approach, we seek continuous improvement in supply chain independence. Plastic injection moulding equipment with robots and highly automated moulding cells is used for production of plastic parts and casings.

electronics

manufacturing journey

Click here to discover the comprehensive PCB assembly process, from start to finish.

Click here to discover the comprehensive PCB assembly process, from start to finish.

We emphasize agility within the electronics manufacturing team to ensure that requests from our partners are given priority. As a team we act flexibly, communicate and then execute tasks quickly.

Focused on precise operational execution, guaranteeing the finest quality. Above all, we aim to create value, fulfil our promises and help by being a truly reliable partner.

Our customer-focused team understands the importance of a close relationship between electronics manufacturing team and the product owners. To support your success, we devote our time, effort and energy to an effective partnership.

WORK SMARTER WITH EMS PARTNER